DESCRIPTION

In ceramic industries, cost of fuel is about 40 to 45% of total cost of product and cost of fuel is increasing high & high in every month. Cost of product can be reduced by energy conservation. Using good quality & insulation materials in kiln can save energy. Insulator brick & blocks should have high porosity, low bulk density, high cold crushing strength (CCS), low permanent linear changes after firing (PLCR) and low thermal conductivity.

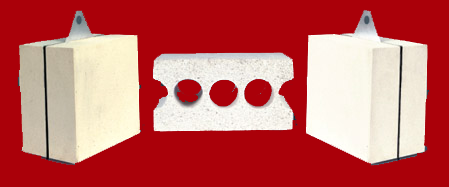

Shivam Hot face insulating bricks and blocks “HFK – 451” and high alumina porosint “P – 451” have all above properties. Products like HFK Bricks, HFK Insulation Bricks and Porosint Bricks give very good result in roller hearth & tunnel kiln.

Product Details

| Properties | UNIT | SC – HFK (R) | SC – HFK (SP) | SC – 23 | SC – 26 | SC – 28 |

|---|---|---|---|---|---|---|

| Maximum Hot Face Temperature | °C | 1350 | 1400 | 1260 | 1400 | 1540 |

| Bulk Density | gm / cc | 0.92 | 1.1 | 0.7 | 0.8 | 0.85 |

| Cold Crushing Strength | Kg / cm² | 25 | 50 | 10 | 18 | 19 |

| Reheat Change (24 hrs. Testing) | % | 0.2 at 1200 °C | 0.2 at 1350 °C | 0.7 at 1250 °C | 0.2 at 1350 °C | 0.2 at 1500 °C |

| Apparent Porosity | % | 65 | 57 | 71 | 71 | 71 |

| At 400 °C Hot Face Temperature | 0.28 | 0.30 | 0.14 | 0.18 | 0.28 | |

| At 800 °C Hot Face Temperaturee | w /m °K | 0.32 | 0.35 | 0.24 | 0.32 | 0.32 |

| At 1200 °C Hot Face Temperaturee | 0.37 | 0.40 | 0.3 | 0.38 | 0.39 | |

| Al2O3(Min.) | 32 | 40 | 32 | 50 | 60 | |

| Fe2O3(Max.) | % | 1 | 0.7 | 1 | 0.7 | 0.6 |

| TiO2 (Max.) | 1.5 | 1 | 2 | 1 | 0.7 |